Q235 Materail Friction Bolts Metallic Mines Supporting Tool

Description Of Q235 Materail Friction Bolts:

Friction bolts (also known as friction stabilizers or split-set bolts) represent a fundamental and highly efficient ground control system extensively employed in underground mining operations. Engineered for rapid deployment, they deliver immediate reinforcement to rock masses, significantly enhancing safety by mitigating the risks of rockfalls and roof collapses immediately after installation.

Specification Of Q235 Materail Friction Bolts:

|

Dimensions

|

33

|

39

|

47

|

|

Taper diameter (mm)

|

28

|

30

|

38

|

|

Taper length (mm)

|

60

|

65

|

65

|

|

Slit width C (mm)

|

13

|

16

|

22

|

|

Thickness (mm)

|

2.5/3.0

|

2.5/3.0

|

2.5/3.0

|

|

Bolt size (mm)

|

33

|

39

|

47

|

|

Length (mm)

|

900-2400

|

900-3000

|

900-3700

|

|

Drill hole diameter (mm)

|

31-33

|

35-38

|

43-45

|

Application Of Q235 Materail Friction Bolts:

Copper Mines

Gold Mines

Other Metallic Mines

The installation process is streamlined and highly efficient. Using conventional drilling equipment, the bolt is forcefully inserted into a pre-drilled hole of a specific diameter. As the slightly larger-diameter bolt is driven in, it compresses against the surrounding rock, generating immense axial and radial frictional forces along its entire length. This action effectively binds and secures unstable rock strata, creating a massive supporting force that ensures the stability of roadways, tunnels, and other excavated spaces.

Feature Of Q235 Materail Friction Bolts:

These bolts are manufactured from high-yield, high-strength steel to guarantee superior durability and load-bearing capacity. A critical design feature is the high-integrity welded ring at the bolt's head. This ring maintains a powerful grip on the rock surface and is engineered to remain securely anchored even in the unlikely event of a bolt body fracture, preventing sudden and catastrophic support failures. To suit different environmental conditions, they are available in a standard black (uncoated) finish or with a hot-dip galvanized coating for exceptional corrosion resistance in wet or acidic environments.

Advantage Of Q235 Materail Friction Bolts:

Rapid Installation: Can be installed quickly using standard drilling rigs, drastically reducing labor time and operational downtime.

Immediate Support: Provides active reinforcement the moment it is set, ensuring safety without delay.

High Load-Bearing Capacity: Engineered to withstand heavy static loads and dynamic ground movement.

Long-Term Reliability: The hot-dip galvanized option offers extended service life and protection in corrosive mining environments.

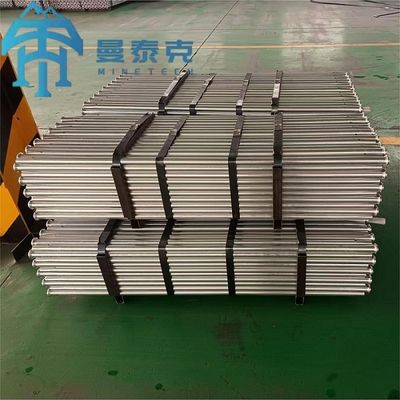

Package Of Q235 Materail Friction Bolts:

For secure storage and transport, our friction bolts are bundled and neatly arranged on pallets.

Company Profile:

Hebei Minetech Machinery Technology Co., Ltd. is a leading manufacturer and exporter specializing in high-quality mining drilling tools, headquartered in Hebei Province, China. With over a decade of industry expertise, our company has established itself as a trusted provider of premium tapered and threaded rods, chisel bits, button bits, and a wide range of other mining drilling equipment. With our rich experience and professional engineering team, we focus on providing complete solutions for mining machinery.

Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!  Twoja wiadomość musi mieć od 20 do 3000 znaków!

Twoja wiadomość musi mieć od 20 do 3000 znaków! Proszę sprawdzić email!

Proszę sprawdzić email!